Firmware updates delivers high-definition capabilities to Stratasys Selective Absorption Fusion 3D printing technology

Table Of Content

- Architected materials

- D printing and other applications

- Best design software for additive manufacturing

- Stochastic reconstruction of digital porous domains

- Universal scaling laws of keyhole stability and porosity in 3D printing of metals

- Cost

- Material Jetting and Stereolithography

- Influence of FDM process parameters on tensile strength of parts printed by PLA material

A difference between the design and the printed sample, or defects, for example, a deviation in terms of porosity or unintended cracks induced during post-processing of printing, can be directly detected. As a means of validation, a quantification via numerical and experimental investigation, for instance, permeability estimation, would be preferable since this can provide further insight into flaws and deviations20,21,31,48 on an REV scale. In addition, after the validation, the representativeness of the sample could be evaluated via subsequent numerical investigation on its domain size. In the study of Ishutov et al.33, the authors investigated a proxy which was created by using ProJet 660 Plus 3D printer with the binder jet technique.

Architected materials

With the advancements in organic CAD abilities, you can actually use natural flowing structure for functionality rather than simply aesthetics. Many software can analyze your CAD designs and optimize them for handling actual stress and strain. The process as a whole ensures your parts are strong, but removes virtually every bit of unneeded material, saving both you and the client a lot of money in possible excess material costs. Additive manufacturing is held up by the various technologies and software that are constantly improving and shaping the industry.

D printing and other applications

You can also overcome the size limitations of metal AM technologies by 3D printing a sand pattern and then casting an alloy of your choice. For example, using design automation, you can automatically run a topology optimization to lightweight 30 components in a single day instead of 30 days. Similarly, you can quickly generate 3D printed fixtures to support conventional manufacturing processes with a few clicks. The way to achieve this is by creating self supporting structures or by following the shell and infill approach.

Best design software for additive manufacturing

Given the relative newness of additive manufacturing, researchers are still trying to understand the many different aspects of it, how the materials work together, and how to decrease the likelihood of defects in final parts. Technically, additive manufacturing can refer to any process where a product is created by building something up, such as molding, but it typically refers to 3-D printing. This strategy is all about discovering the optimal distribution of material to maintain crucial specifications for a part, such as weight, stiffness, and strength.

Stochastic reconstruction of digital porous domains

Therefore, only the region of interest of the sample would be considered in the final output of the segmentation. This work was conducted with the Image Processing Toolbox from Matlab©70 (The MathWorks, Inc.). We should note here that the digital domains are isotropic by design (assuming that they are large enough to contain a representative number of pores) and it is therefore expected that they exhibit the same permeability in all three directions. Traditional computer-aided design (CAD) tools like Pro/ENGINEER, Catia and Siemens NX (formerly known as Unigraphics) were created with subtractive manufacturing in mind. These types of design tools take the approach where, if you want to create a hole in a block, for example, you would drill one into it. Additive manufacturing is a powerful approach, but sometimes by combining it with traditional methods such as casting or injection molding, new and exciting opportunities present themselves.

Universal scaling laws of keyhole stability and porosity in 3D printing of metals

Consolidating parts may be an obvious advantage with 3D printing; additive manufacturing processes enable the production of geometric shapes that otherwise require assembly of multiple parts. Component consolidation can dramatically decrease costs, increase production speed and heighten functional performance on the production floor. For example, General Electric Aviation was able to replace 900 parts with 16 in building a helicopter engine using additive manufacturing technology. Bones and tissue have been proven to bond far better with roughly latticed material rather than smooth manufactured parts. Most latticing design software allows you to design micron-accurate randomized latticed structures into your components to perfectly fit your client’s needs. Bone growth is improved with randomly latticed parts as well as the increased ability to provide a solid yet organic interface for the body to begin healing around.

Cost

Additive manufacturing may look simple, but the entire design process requires a significant depth of technical knowledge and clear communication between parties to ensure high quality. From the first sketch to the final part design and build, it’s important to have a strong understanding of the full design process and how it can impact your projects. Aerojet Rocketdyne used an internal self supporting lattice structure to ensure that the production of Mark II of their spacecraft quad thruster injector block was economically viable. Generative design is a design methodology that uses computational algorithms to generate high-performance geometry based on specific requirements. Cobra Aero completely reimagined the UAV drone engine cylinder taking advantage of the benefits of additive manufacturing.

Such a technique also offers shock absorption and impact protection, particularly interesting in cycling, for example. One of the key benefits of additive manufacturing is that producing one-off, unique design is economically viable. However, even though the cost of production is low, the cost of engineering these complex parts is not. The basic ideas behind generative design may not sound very different from the traditional iterative engineering design process. However, generative design is the next frontier in mechanical engineering product development because it flips the paradigm of first creating and then evaluating the performance of a design candidate. Another core application of architected materials is the development of medical implants that feature lattice structures that promote bone growth.

Taking proactive steps to address these misconceptions and equip people properly will be key in solving the issue. Established businesses can also evaluate whether additive manufacturing can be part of their business models. If a company produces products that are specialized or would benefit from the ability to have complex geometries, it will have to determine whether additive manufacturing would improve its products. Companies like Adidas are using additive manufacturing to create sneaker soles at speeds that may make it suitable for mass customization.

The convergence of Additive Manufacturing and AI - Metal Additive Manufacturing magazine

The convergence of Additive Manufacturing and AI.

Posted: Thu, 21 Dec 2023 08:00:00 GMT [source]

Additive manufacturing (AM) processes fabricate parts in a layer-by-layer manner by which materials are added and processed repeatedly. This article introduces the general concepts and approaches to design for AM (DFAM) and outlines important implications for part characteristics, design opportunities, manufacturing practices, supply chains, and even business models. It presents contrasting perspectives on DFAM, followed by a discussion on more general and overarching opportunistic design methods and on design for constraints, similar to conventional DFM. It concludes with a presentation of a design approach to the AM process chain, acknowledging that AM-fabricated parts typically undergo several postprocessing steps and that it is important to design taking into account these steps.

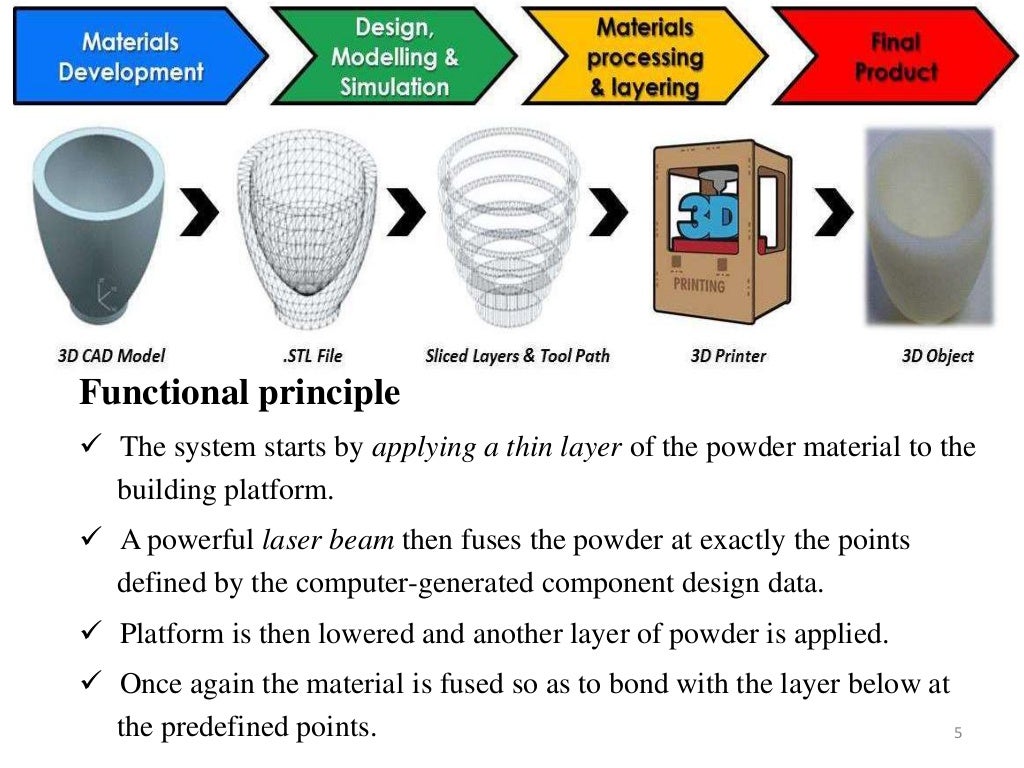

Or where small lot sizes or customization makes it less expensive to manufacture an object additively than traditionally. When transitioning your part to injection molding, remember to adjust part geometries to address injection molding’s DFM rules, and some design elements might not transition at all. Also, think about how material will flow through a mold to ensure sharp corners get filled. While the build depends on the process you choose (e.g., SLA, DMLS), the idea is the same. The printer “draws” a thin layer of material, and it cures a bit before the next layer is added.

Computational Design in 3D Printing for Mass-Customization - All3DP

Computational Design in 3D Printing for Mass-Customization.

Posted: Tue, 15 Aug 2023 07:00:00 GMT [source]

There are a few industries where 3-D printing parts or products makes more sense than manufacturing them traditionally. Aerospace, racecars, and the medical field are all industries where additive manufacturing can make inroads. This end of product-life use of additive manufacturing could be useful even for companies that have never used the technology before, said Roemer. Companies like Caterpillar, which ships replacement parts within 24 hours, could have 3-D printers set up at strategic locations to print and deliver those parts instead of keeping inventory stocked at those locations.

When a lattice is randomized organically, the adhesion to organic surfaces through healing increases drastically. Only additive manufacturing allows you to design medically optimized parts with latticing, and there are few better ways to customize engineering design for the medical industry. Equispheres is a private company developing innovative technologies for the production and use of advanced materials, for instance, high-performance aluminum powder for additive manufacturing (3D printing) applications.

But with additive manufacturing, setup costs are mostly eliminated, so creating just a handful of objects becomes more reasonable. This makes customizing products, like prosthetics or implants, easier, and could result in better outcomes for patients. Hearing aids, which are customized for each person, are almost entirely additively manufactured. With traditional manufacturing, the entire supply chain can take months and require an investment — sometimes millions or billions of dollars — that can only be recouped by high-volume production. With additive manufacturing, much of the supply chain’s intermediate steps are removed. “The speed at which you can get to a single part is much faster,” said Roemer, since people can send a design directly from their computer to the 3-D printer.

The study also underscores the significant impact of process parameters and alloy chemistry on she most sustainablepecific energy consumption for atomization. Mechanical milling, especially ball milling, was shown to reduce specific energy consumption notably when compared to gas atomization. An excellent example of this is the 3D printing of glasses and eyewear — a niche field that EOS has considerable experience in.

It also allows you to validate manufacturability and introduce necessary changes to part geometries, orientations and supports. Architected materials are structures with a tailored mechanical, biological, thermal, or electromagnetic response. In practice, architected materials are created by closely controlling and manipulating the properties of lattice structures, surface textures, or other repeated patterns to create highly customizable and digital metamaterials. In the past, 3D printing was considered only a rapid prototyping solution or an alternative method to producing spare parts without significantly altering the geometry.

Comments

Post a Comment